At Sturges in addition to weaving engineered narrow fabrics, we design, cut, sew, and test in-house, positioning us as a uniquely capable and qualified partner for your custom sewn products. Using our diversified inventory of webbing, thread, and hardware, we have the means and expertise to identify your problem, design, and manufacture a unique solution. Learn more about our custom sewing services.

OPPORTUNITY

We understand each challenge is an opportunity. The first step in the design process is to identify the challenge the customer is experiencing. A customer recently reached out to Sturges and explained they were having issues with the stitches tearing out of their current product. The customer expressed the sewn product would need to withstand a 5,000 lb pull test under ambient conditions.

SOLUTION

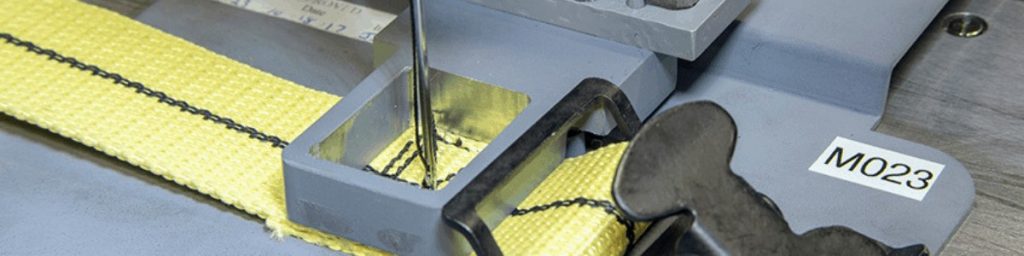

After an in-depth conversation with the customer’s engineering team, we agreed the material and design were not an issue and could remain the same. The problem was identified to be the pattern of the stitch. By changing the stitch pattern and coordinates, we could drastically increase the product’s performance – beyond our customer’s expectations.

TESTING

The design process is not complete until it is thoroughly tested and is deemed process capable. The Sturges Test Lab is equipped with the necessary equipment to validate designs through standard test methods as well as documented custom methods. For this unique application, our 35,000 lb vertical tensile tester was utilized to verify the strength of the stitch. The sewn product was pulled at 3″ per minute until failure. The stitch failed when the drop in peak load was greater than 90%. We were able to surpass the customer’s requirement and achieve over a 6,000 lb stitch. After testing, the results were shared in a formal test report with data and pictures. Samples were sent shortly after for customer approval, and once the samples were verified again in their lab, and their engineering team approved the change, Sturges was selected as the new supplier.

FEEDBACK

“It was a pleasure to work with Sturges. Sturges did a great job working with us to develop the exact strap that we wanted.”

Our industrial sewing capabilities can produce a custom-sewn strap that exceeds your expectations.